Why is wire length critical for an SPD?

Surge Protection Device

(SPD) is an electrical device that absorbs the fast-rising voltage spikes and

surges from the voltage line. The lead lengths of the SPD play a significant

role in SPD’s performance. The performance of an SPD is measured in Voltage

Protection Rating (VPR), a number generally given by the UL/ETL with their UL1449

test reports.

What is VPR in a Surge protection device?

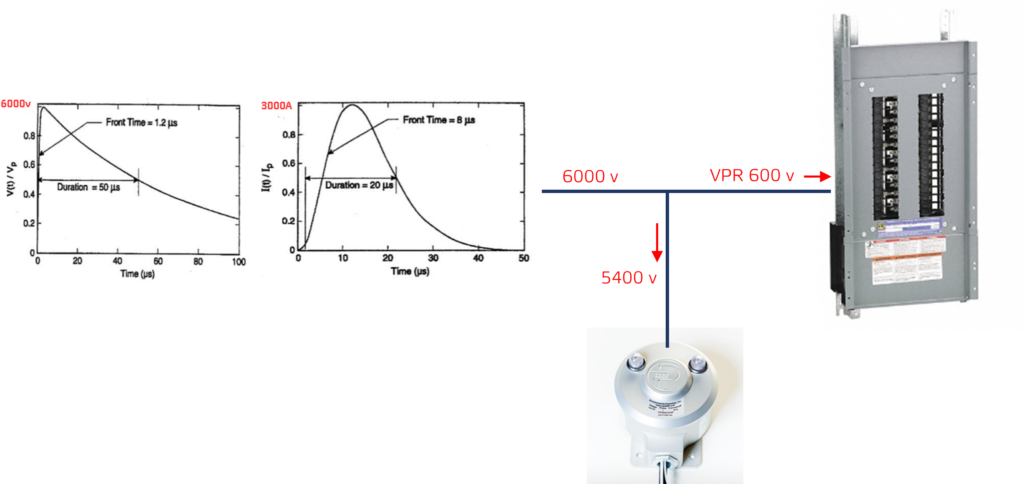

SPD is usually connected to the main panel to protect the downstream devices or the wall receptacle to protect the electronics (unprotected devices). VPR is the clamping voltage measured by the SPD after it passes through a 6kV 1.2/50us, 3kA 8/20us combination surge waveform. In other words, it’s the let-through voltage that the SPD leaves to its downstream (electrical panel in your home or unprotected electronics) after it is subjected to the 6kV, 3kA 8/20us combination surge. The higher the VPR, the weaker the SPD performance because SPD is leaving out a larger surge to the load. Ex: An SPD with a VPR of 800V has a lower performance than an SPD with 600V, as the former gives 200V more considerable surge than the latter to the unprotected device. The following picture demonstrates how an SPD let-through voltage to the electrical panel.

Why does the lead length affect the surge protection device performance?

The lead length of the

SPD plays a vital role in the SPD’s performance. The inductance of the wire varies

with the lead length, altering the SPD performance. The surge is 8/20us, a much

higher frequency signal to the SPD than the fundamental 60Hz signal. The

circuit behavior of the SPD is different with the higher frequency signal

compared to the nominal AC waveform at 60 Hz. The SPD behaves like a high

impedance circuit when it passes with a high-frequency signal (surge). The

higher the impedance, the higher the device’s resistance to absorbing the

surge, and hence it will leave more surge (VPR) to the panels downstream – as

the SPD is usually connected in parallel to the electrical panel.

How much performance change will the lead length cause on an SPD?

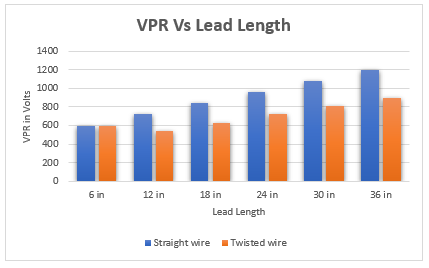

On average, SPD’s VPR increases by

20v per additional 1 inch of the wire. UL specifies to test and release the VPR

number with a standard 6-inch length lead length. Therefore, the manufacturers

set VPR from their cut sheets with a 6-inch lead-length wire. The research and

testing show that the VPR increases by an average of 20v per additional 1 inch

of wire length. Ex: If an SPD has a VPR of 600v at 6inch, it will have a VPR of

600v+ (4*20) = 680v at 10 inches. In other words, with an additional 4in SPD lead

wire, your downstream electrical loads are receiving an extra 80v surge (that

nobody likes). Likewise, a three feet lead wire on the same SPD will pass

through 600+(30*20) = 1200V, dangerous enough to damage your electrical load.

What if I cannot trim the lead length to 6 inches?

While keeping the lead lengths to 6in is highly recommended, it is not quite possible for every field installation considering the placement of panels. In the cases where the lead lengths are more than 6 inches, it is highly recommended to twist the SPD leads to negate the impedance and the surge. You could decrease the VPR by an additional 25% with the twisted wires. Ex: If the SPD has a VPR of 1200V at 36-inch straight wires, it will have a VPR of 900V with the twisted wires. The following picture shows the twisted wires on an industrial surge protection device.

It is also recommended not

to have any bends or loops in the wires. The bends and loops increase the wire

inductance, decreasing SPD performance. The following graph summarizes the lead

length, twisted wires vs. the VPR.

Conclusion

The lead length of the surge protection device makes a significant impact on the SPD performance. The following guidelines are recommended when installing a surge protection device in any facility:

1) Run the straight wires without bends and loops if the lead lengths are 6 inches and under

2) Twist the wires to negate the impedance and increase the VPR by 25% when the lead lengths are more than 6 inches.

Environmental Potentials, Inc (EP) manufactures patented Surge Protection Devices that are UL 1449 4th Ed tested. EP uses a premium quality larger wire that could also increase the SPD performance in lowering the VPR numbers. The EP offers additional waveform correction and SPD capabilities with its patented technology. Made in the USA, the EP provides 100% protection 24/7 from surges and noise. Contact us for more information