The New NEC code requirement for SPDs

Adopted in all 50 states, NFPA 70, National Electrical Code (NEC) is the benchmark for safe electrical design, installation, and inspection to protect people and property from electrical hazards. The NEC is revised every three years, with the recent revision in 2020.

Article 230.67 of the NEC 2020 is a newly added section requiring all services supplying dwelling units to be installed with Type 1 or Type 2 SPD. A Dwelling unit can be a townhome, condo, single family, or each unit in a multifamily or an apartment. In plain English – All the service panels supplying the residential units must be protected by a Type 1 or Type 2 SPD. This requirement will also apply to upgraded services on dwelling units.

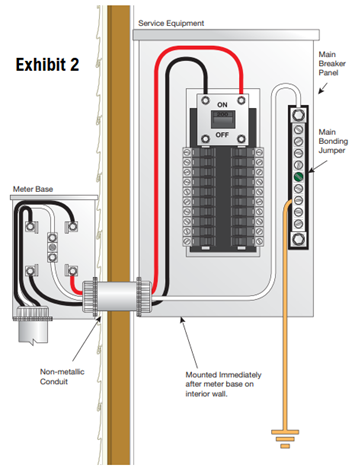

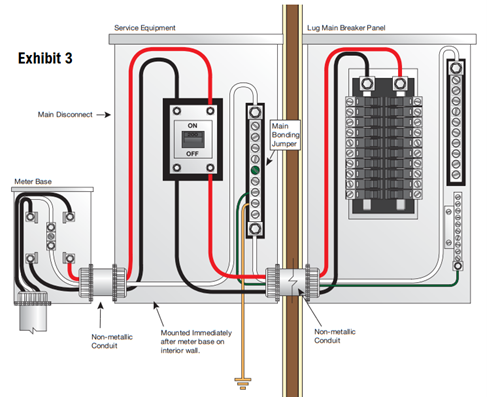

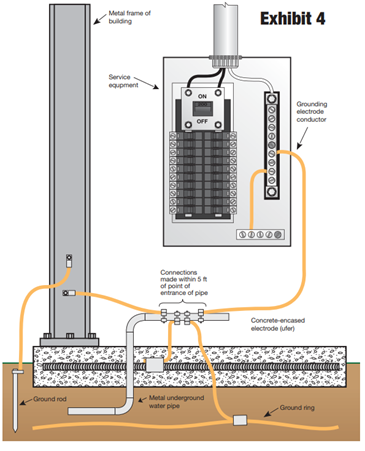

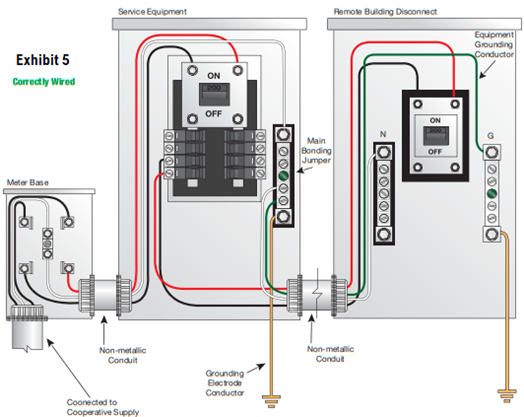

230.67 Surge Protection. (A) Surge-Protective Device. All services supplying dwelling units shall be provided with a surge-protective device (SPD). (B) Location. The SPD shall be an integral part of the service equipment or shall be located immediately adjacent thereto. Exception: The SPD shall not be required to be located in the service equipment as required in (B) if located at each next level distribution equipment downstream toward the load. (C) Type. The SPD shall be a Type 1 or Type 2 SPD. (D) Replacement. Where service equipment is replaced, all of the requirements of this section shall apply.

What is an SPD?

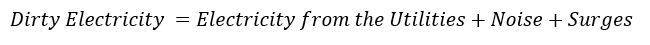

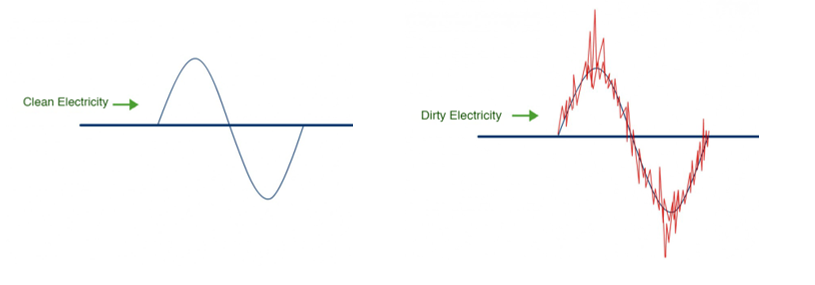

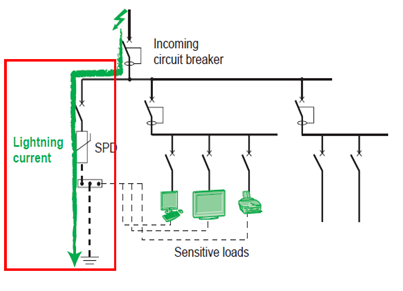

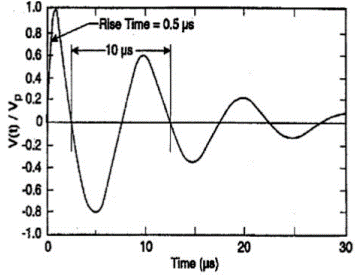

SPD is Surge Protective Device that limits the overvoltage, surges, and spikes on an electrical line to protect the loads. In the event of surges, the electrical loads are subjected to excessive harmful overvoltage that could damage the load instantly. The SPDs installed at the electrical panel will absorb and divert the overvoltage so the loads will never have to face the damaging effects of the surges.

The SPD’s are classified into Type 1 and Type 2 categories depending on their installation locations. Type 1 SPDs are installed between the secondary of the service transformer and the line side of the main service disconnect. Type 2 SPDs are installed after the main service disconnect, or at load side of the main breaker.

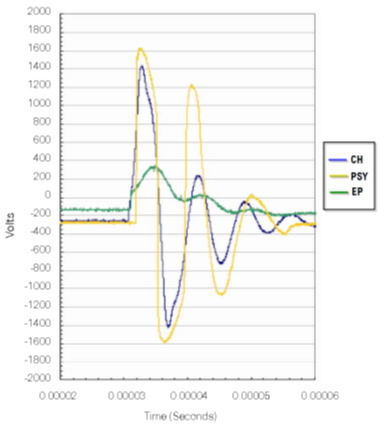

EP is beyond an SPD

EP technology is classified as Type 2 SPD, tested under UL1449 4th Ed for its surge suppressing capabilities. EP technology combines an SPD and a patented EMI filter to remove harmful high-frequency noise from the electrical system. Our technology protects your home from the damaging effects of surges, transients, noise, and other dirty power. All our products are patented, proven, and made in the USA.

Contact

EP sales at sales@ep2000.com to know about your local distributor. A certified

electrician is required to install the EP filter on your main electrical panel.

EP’s licensed electricians can help you install the product in all 50 states.